This unique system provides automatic stable heat (embers), causing the fan to switch off when the level of the fuel decreases. This accurate detection maintains the hot embers layer in the combustion chamber for several hours, reducing the number of times a new fire is started in the boiler per season. If the user fails to insert more fuel, a layer of unburnt carbon (in the form of charcoal) remains in the furnace, which is ideal for the next firing of the boiler without the need to clean the furnace. Just ignite the layer with a piece of paper, and you can add big logs of wood directly. An original solution that is patented.

The built-in thermostat with a temperature setting at 60°C and a special structure for mixing inside the boiler protects the boiler. Option of gravity connection to the storage tank without pumps. Considerable savings during installation and safe operation. 7-year warranty on the boiler body, with no additional conditions. An original solution that is patented.

which ensures uniform burning of fuel and allows to burn fuels of various dimensions (wood chips, sawdust, briquettes even lower quality). Pre-drying air, which is supplied (if necessary) into the upper part of the chamber will dry up any damp fuel in order to be able to burn it well and maintain high boiler efficiency and low emission values.

Where the walls of the stoking chamber are not directly cooled by water – they are hotter, which prevents condensation. The service life of these boilers is many times longer than that of conventional gasification boilers. It also allows the combustion of moist fuel, without significantly reducing the boiler‘s service life. The increased temperature of the walls prevents the unpleasant deposition of tar in the stoking chamber. The compact gasification chamber is a separate element that is insulated from the walls of the water boiler. The chamber can be replaced.

with a burn time of up to 8 hours. Along with the stable heat, it can take up to 24 hours to next fuel stoking.

Controlled by an external lever have an original and precise construction. They ensure consistent cleanliness of the exchanger and maximum efficiency boiler operation at all times.

Provides automatic ash removal from the combustion chamber during combustion, completely eliminating the need to clean it before firing it up again.

for comfortable stoking of wood and loose fuels (woodchips, sawdust, etc.) in the entire combustion chamber volume.

Allows you to set the required boiler output in percentages and regulate the boiler with continuous operation. Setting reduced power will ensure a long period of combustion in the boiler, at a quality comparable to the quality at 100 % power. This solution allows the boiler to operate at a lower output (especially important in the transition period), as well as the installation of a smaller storage tank, saving expenses and space.

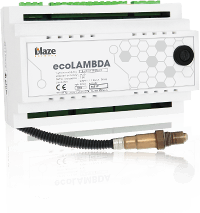

Provides high quality combustion and low emission values, whether you burn hard or soft wood. The lambda probe is an important element that measures the residual oxygen value and then, with an actuator, controls the amount and type of incoming combustion air.

Provides high quality combustion and low emission values, whether you burn hard or soft wood. The lambda probe is an important element that measures the residual oxygen value and then, with an actuator, controls the amount and type of incoming combustion air.

Pre-drying a primary air are open at 100 %, secondary air is completely closed. In this position you can find the air supply curtain in case of burning damp wood or big logs.

Secondary air is open at 100 %, pre-drying and primary air are completely closed. In this position you can find the air supply curtain in case of burning dry wood or briquettes, where is a need for bigger amount of secondary air for high quality combustion.

Primary and secondary air open at 50 %, pre-drying air completely closed. You can find the air supply curtain in this position during combustion of standard fuel.

The relative air ratio is determined by the multifunctional movable curtain, which may be controlled manually or with actuator and lambda probe. Unlike other boilers, the BLAZE HARMONY boilers can easily control the distribution of the air entering the fuel (pre-drying air is supplied over the fuel). Therefore the boiler can be adapted to various fuels. This effectively burns fuel that can be easily burn (wood chips, small briquettes), but also fuels that burns hard (large logs, wet wood).

Stocking - after stoking fuel to whole volume of the stoking chamber the combustion time is up to 8 hours depends on the fuel type and preset boiler output.

After 8 hours - when the fuel level decrease under the detection threshold, then the sensor sends signal and controller switch off the fan. This stops the burning process.

Up to 24 hours from the first fuel stoking, there are still hot coals (embers) in the chamber, so it is sufficient to add directly bigger logs, start the fan and combustion continues.

After 24 hours and more after first fuel stoking there will not be hot co- als (embers). There will remains fuel residual in the form of charcoal. In such a case is suifficient to start the fan and with small piece of paper fire up the layer of charcoal.

After short time the charcoal fires up very well.

Then it is possible to add even larger pieces of wood. The residual fuel detection mechanism provides user‘s high operation comfort due to lack of new ignitions, when user must clean the boiler and cut small pieces of wood and wait until the boiler ignites successfully.

Gasification boilers BLAZE HARMONY are prepared for later conversion to automatic combined boiler, whichallows pellet combustion. This solution means for user increasing of comfort after installation of the pellet burner, when after the wood burns off, the boiler operation continues automatically with pellet combustion.

For the conversion of wood gasification boiler to combined boiler for wood and pellets is sufficient to buy conversion set which includes:

Boilers BLAZE HARMONY

are equipped with controller, which after connection the additional module allows to control the pellet combustion and control the elements of burner, pellet feeder including. It is not neccessary to change complete controller because of the boiler conversion.

| BH 18 | BH 25 | BH 33 | |

|---|---|---|---|

| mm | mm | mm | |

| A | 568 | 752 | 752 |

| B | Ø147 | Ø147 | Ø147 |

| C | 1365 | 1365 | 1365 |

| D | 1404 | 1404 | 1404 |

| E | 424 | 608 | 608 |

| F | 138 | 138 | 138 |

| G | 295 | 295 | 295 |

| H | 670 | 670 | 670 |

| I | 880 | 880 | 880 |

| J | 640 | 640 | 640 |

| K | 526 | 526 | 526 |

| L | 50 | 50 | 50 |

| X,Y | G6/4" | G6/4" | G6/4" |

| Z | G1/2" | G1/2" | G1/2" |

| BH 18 | BH 25 | BH 33 | |

|---|---|---|---|

| Nominal output (kW) | 18 | 25 | 33 |

| Efficiency (%) | 92 | 92 | 91 |

| Emission class | 5 | ||

| Ecodesign | YES | ||

| Energy class | A+ | ||

| Logs length (mm) | 330 | 500 | 500 |

| Stocking chamber volume (l) | 100 | 150 | 150 |

| Weight (kg) | 400 | 550 | 560 |

| Maximal operation pressure (bar) | 3 | 3 | 3 |

| Exchanger water volume (l) | 50 | 60 | 60 |

Sophisticated control software allows you to set the required boiler output in percentages and regulate the boiler with continuous operation. The range of possible output settings depends on the type of boiler installed. Setting of lower output will ensure a long period of combustion in the boiler, at a quality comparable to the quality at 100 % output.

This solution allows the boiler to operate at a lower output (especially important in the transition period), as well as the installation of a smaller buffer tank, saving expenses and space.

The controller also evaluates the O2 values measured by the lambda probe and controls the actuator of the primary, secondary, and pre-drying air curtain in order to maintain the set value of residual O2.

After connection of additional module this controller also controls the operation of the burner and pellet combustion, when it fluently modulates with burner output in whole range and thanks to that keeps required boiler temperature.

Internet system ecoNET provides to user option for remote control of the boiler and heating installation. Thanks to that user has possibility to change almost all parameters of boiler and heating system operation, but also view the history of the operation which is is displayed on a clear graph.

Remote acces to controller is possible from every device which is connected to internet, as it is tablet, laptop or mobile phone. Settings can be made via a web browser on www.econet24.com or through a mobile application which is available for Android and iOS.

Online service. The internet system is not only for user. It is useful also for service company, which may have access to the boiler data and if neccessary the service company can change the controller settings. The internet system lowers the costs for service intervention significantly.

Remote control panel with room thermostat function ecoSTER TOUCH allows you to control and change the boiler’s settings from the place, where is the thermostat installed, for example the living room.

Allows controlling of another two mixing circuit and their pumps. Also it allows to control circulation pump for HDW.